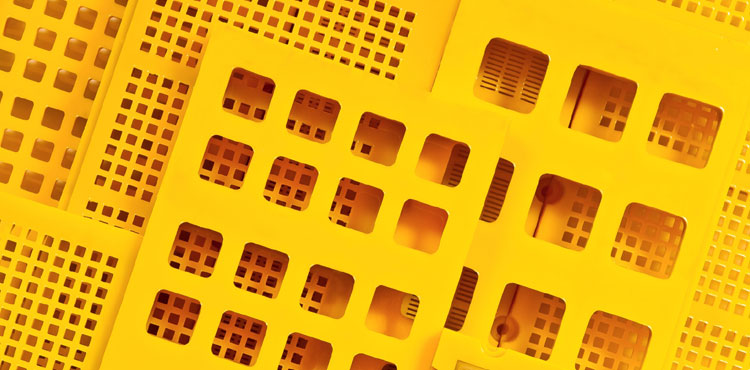

PU Dewatering Screen Panel

PU Dewatering Screen Panel(1.0-4.0mm)

PU Dewatering Screen Panel(1.0-4.0mm)

PU Dewatering Screen Panel: 305*305*30mm screen seam 4.0mm

Outline dimensions can be customized: 305*610, 500*500, 600*600......

Custom stitching dimensions: 1, 1.5, 2, 2.5, 3, 4

Available mounting methods: expansion screws / bolts

Application of PU Dewatering Screen Panel:

Dewatering Screen is widely used, now Polyurethane Dewatering Screen panel has been more and more people understand, and gradually replace all kinds of rubber sieve plate, metal sieve plate. Macroporous polyurethane sieve dehydration for coal, iron ore, copper, gold and other mineral material grading, screening, dewatering, sand separation, The dewatering screens vibrating is the necessary accessory of the mineral processing equipment and screening plant, The PU dewatering screen panel can greatly improve the working efficiency.

Characteristics of polyurethane dewatering screen panel:

- Polyurethane screen panels is high wear-resistance and with long service life.

- Polyurethane dewatering screen and material friction coefficient is low, non-stick material, no hole, high screening efficiency.

- Polyurethane sieve plate assembled by the module is lightweight and with simple installation. Besides, it can be conveniently replaced.

- Polyurethane sieve plate with strong shock absorption and low noise.

Crusher Spares Coimbatore (CSC) outstanding manufacturer of polyurethane products. It has advanced mechanical processing equipment. We had established a long-term cooperative relationship with many domestic mines and vibrating screen machine manufacturers. The polyurethane mesh produced in CSC has been unanimously approved by customers at their industries. If you want to buy a good quality polyurethane sieve plate, welcome to contact us: cbecrusherspares@gmail.com. You can provide us with samples or drawings, we will meet your satisfaction.

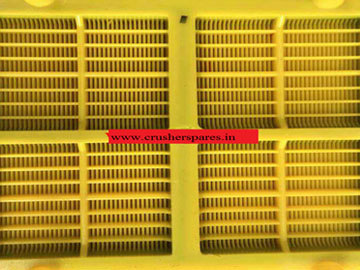

Dewatering Screen

Product Details:

- Sieving efficiency 56% - 85%

- Mesh 0.15-0.3 mm

- Sieve area 4 m2

- Material PU

- Aperture size 0.1-2.5

- Thickness 35mm,40mm,50mm

Our firm is occupied in presenting a wide range of Dewatering Screen.These are extremely utilized in the market for various purposes.We make these products using the sophisticated techniques and optimum quality raw material which is procured from reliable retailers of market.In addition, we present our products in the market at pocket-friendly prices.

Features:

- Simple and efficient for segregation of different sizes of material

- Made of wire mesh

- Plates rolled in different dia sizes and perforations

- Last for long time period

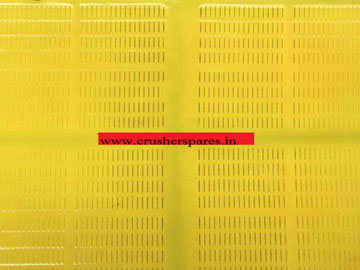

Polyurethane Dewatering Screen Panels ( Water separation screen )

Abrasion resistance is very prominent, and the test results are generally in the range of 0.03 ~ 0.20mm3/m. The abrasion resistance of the Polyurethane Dewatering Screen is about 3~5 times of that of the natural rubber.

In actual use, because of the influence of lubricant and other factors, the effect of Polyurethane Dewatering Screen is often better. Wear resistance is greatly related to the tearing strength and surface condition of the material

The tear strength of the Polyurethane Dewatering Screen is much higher than other rubber, but the friction coefficient of the polyurethane sieve plate itself is not low, generally above 0.5, which requires attention in the actual use of added oil lubricant, or add a small amount of graphite or molybdenum disulfide, silicone oil, PTFE powder, in order to reduce the friction coefficient, reducing friction.

The friction coefficient of the Polyurethane Dewatering Screen is also related to the material hardness and surface temperature. In all cases, the friction coefficient increases with the decrease of hardness, and increases with the increase of surface temperature. The maximum value is about 60 degrees centigrade

Products List

- PU Dewatering Screen Panel

- Spring Steel Wire Meshes

- Conveyor Rollers & Stand

- Horizontal Shaft Impactor(HSI)

- Vertical Shaft Impactor(VSI)

Contact Us

+91-90954 07111+91-90953 07111

+91-98428 16716 cbecrusherspares@gmail.com

No:2, Azad Nagar, Opp JB Mahal,

Karumbukkadai ,

Coimbatore-641 008